Best Legs for Live Edge Tables: A Comprehensive Guide

Live edge tables, with their organic forms and unique character, have become a popular choice for homeowners and designers alike. The inherent beauty of a live edge slab demands careful consideration when selecting complementary legs. The right legs not only provide structural support but also enhance the overall aesthetic, contributing to the desired style and functionality of the table. Choosing the "best" legs is not a one-size-fits-all answer. It depends on the specific slab, the intended use of the table, the desired style, and the budget constraints of the project. This article explores various leg styles suitable for live edge tables, examining their strengths and weaknesses to guide informed decision-making.

Before diving into specific leg styles, it is crucial to assess the live edge slab itself. Consider its dimensions (length, width, and thickness), the character of the live edge (smooth, jagged, or heavily textured), and the overall weight. A heavier slab necessitates sturdier legs to ensure stability. The dimensions of the room where the table will reside should also be factored into the leg selection process. Overly bulky legs can overwhelm a smaller space, while delicate legs may appear insignificant under a large slab in a spacious room.

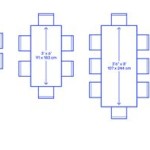

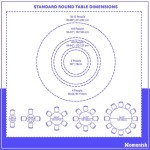

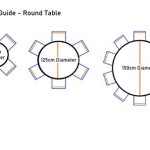

The intended use of the table will also influence leg selection. A dining table requires robust legs that can withstand daily use and potential bumps and scrapes. A coffee table, on the other hand, might allow for more decorative or less structurally demanding leg options. Furthermore, the desired height of the table will directly impact the leg length. Standard dining table height is typically around 30 inches, while coffee tables generally range from 16 to 18 inches.

Key Point 1: Exploring Metal Leg Options

Metal legs are a popular choice for live edge tables, offering a modern and industrial aesthetic. Steel is the most commonly used material, prized for its strength, durability, and versatility. Metal legs can be fabricated in a wide variety of shapes and sizes, catering to diverse design preferences. Different finishes, such as powder coating, raw steel, or brushed metal, allow for further customization.

One prominent style is the hairpin leg. Hairpin legs are characterized by their slender, angled metal rods, creating a minimalist and airy feel. They are available in various heights and thicknesses to suit different slab sizes and weights. Hairpin legs are particularly well-suited for smaller live edge tables, such as coffee tables or side tables, as they do not visually overwhelm the slab. However, it's important to note that hairpin legs, especially thinner versions, may not provide sufficient support for very large or heavy slabs.

Another prevalent option is the trapezoid leg, also known as A-frame legs. These legs offer greater stability than hairpin legs due to their wider base. They are typically constructed from thicker steel tubing or flat bar, providing a robust support system for heavier live edge slabs. Trapezoid legs contribute a contemporary and geometric feel to the table, complementing the organic shape of the live edge. They are well-suited for dining tables and conference tables.

Box-section legs offer a more substantial and industrial aesthetic. These legs are typically constructed from rectangular steel tubing, providing exceptional strength and stability. Box-section legs can be configured in various ways, such as a simple rectangular frame or a more complex geometric design. They are an excellent choice for large and heavy live edge slabs, ensuring long-term durability and minimizing the risk of wobble or instability. The clean lines of box-section legs can create a striking contrast with the natural curves of the live edge, highlighting the inherent beauty of the wood.

For a more unique and custom look, consider custom-designed metal legs. A metalworker can fabricate legs according to specific design requirements, incorporating intricate patterns, artistic details, or integrated features. This allows for a truly bespoke table that reflects individual style and preferences. Custom metal legs can be particularly effective in creating a statement piece that serves as a focal point in the room.

When selecting metal legs, it is essential to consider the gauge of the steel. A thicker gauge indicates a stronger and more durable leg. Inspect the welding joints to ensure they are clean and free of defects. A poorly welded joint can compromise the structural integrity of the leg. Also, consider the finish of the metal. Powder-coated finishes are generally more durable and resistant to scratches and corrosion than painted finishes.

Key Point 2: Considering Wood Leg Options

Wood legs offer a more traditional and organic aesthetic, seamlessly blending with the natural character of the live edge slab. Wood legs can be crafted from various species, each offering unique grain patterns and color variations. Common choices include maple, walnut, oak, and cherry. The choice of wood should complement the color and grain of the live edge slab, creating a cohesive and harmonious design.

Straight legs are a classic and versatile option, providing a clean and understated look. They can be square or rectangular in cross-section and can be tapered for added visual appeal. Straight legs are well-suited for a variety of live edge table styles, from rustic to modern. The simplicity of straight legs allows the beauty of the live edge slab to take center stage.

Trestle legs offer a more rustic and farmhouse-inspired aesthetic. Trestle legs typically consist of two angled supports connected by a horizontal beam. This design provides excellent stability and is particularly well-suited for larger live edge tables. Trestle legs can be crafted from rough-sawn lumber or finished with a smooth, polished surface. They can be stained or painted to match the live edge slab or to create a contrasting accent.

Pedestal bases provide a central support system for the live edge slab. Pedestal bases can be constructed from a single, solid piece of wood or from multiple components joined together. They are available in a variety of shapes and sizes, from simple cylindrical designs to more elaborate sculpted forms. Pedestal bases are particularly well-suited for round or oval live edge tables, providing a balanced and aesthetically pleasing support system.

Splayed legs, which angle outward from the table top, are another contemporary option. Splayed legs add a touch of mid-century modern flair to the live edge table. They can be crafted from solid wood or from laminated wood. The angle of the splayed legs provides added stability and visual interest.

When selecting wood legs, it is crucial to ensure they are properly seasoned and kiln-dried to prevent warping or cracking. Consider the grain pattern of the wood and how it will complement the grain of the live edge slab. Also, pay attention to the finish of the wood. A durable finish will protect the legs from moisture and wear and tear. Applying a clear coat finish can highlight the natural beauty of the wood grain.

Key Point 3: Combining Materials and Considering Mounting Methods

While metal and wood are the most common materials for table legs, combining them can create a unique and visually striking design. For example, metal legs with wood accents or wood legs with metal detailing can bridge the gap between modern and traditional styles. This allows for greater design flexibility and customization.

Another option is to incorporate other materials, such as concrete or stone, into the leg design. A concrete pedestal base can provide a solid and industrial foundation for a live edge slab. Stone legs can add a touch of natural elegance to the table. However, these materials are typically heavier and require specialized fabrication techniques.

The method of attaching the legs to the live edge slab is also a critical consideration. The most common methods include using screws, bolts, or metal plates. Screws are generally suitable for smaller tables with lighter slabs. Bolts provide a more secure connection for larger and heavier slabs. Metal plates can be used to distribute the weight of the slab evenly across the legs, preventing stress fractures in the wood. It is essential to use high-quality hardware and to follow proper installation techniques to ensure a secure and stable connection.

Consider using threaded inserts in the live edge slab to provide a strong and reliable anchor point for the leg hardware. Threaded inserts are metal sleeves that are inserted into pre-drilled holes in the wood. They provide a more durable and secure alternative to directly screwing into the wood.

For large and heavy slabs, it may be necessary to use a combination of attachment methods. For example, using both screws and bolts, along with metal plates, can provide maximum stability and security. Consulting with a professional woodworker or metalworker can provide valuable insights into the best attachment methods for a specific project.

Ultimately, the "best" legs for a live edge table are those that complement the slab's unique character, provide adequate support, and align with the desired aesthetic and functionality. Careful consideration of the slab's dimensions and weight, the intended use of the table, and the available leg styles will contribute to a successful and visually appealing result.

Guide On Diy Live Edge Table With Metal Legs Flowyline Design

Table Legs For Live Edge Tables Lancaster

Steel X Shaped Table Legs W Beam Opening

Diy Live Edge Table With Metal Legs 7 Steps Instructables

Table Legs Black Furniture Diy 506 Faras 28h Set Of 4 For Mid Century Modern Tables Woodworkings Flowyline Etsy

29 Tall Rustic Finish Cast Iron Dining Table Legs Live Edge Ebay

Table Legs Metal Furniture Steel 421 Xeni 28h Set Of 2 For Rustic And Mid Century Modern Flowyline Etsy

The Easy Way To Make A Live Edge Table Youtube

Table Legs And Bases For Hardwood Slab Tops

Top 10 Live Edge Table Legs Ideas Flowyline Design